Aluminum Spandrel Panel for Dummies

Table of ContentsThe smart Trick of Curtain Wall Spandrel Panel Detail That Nobody is Talking AboutGable Spandrel Panel Fundamentals ExplainedThe Main Principles Of Secondary Glazing Panels Gable Spandrel Panel Can Be Fun For EveryoneThe Facts About Replacement Glazing Panels Uncovered

Spandrel glass typically is likewise reflective, which assists it to mask the area behind it.Spandrel panels have to be created on a site-by-site basis by an accordingly certified structural designer. A full layout with architectural calculations have to be offered that includes the factors provided below. You must understand that some of this info might not be supplied by the truss roofing system maker or wood framework panel producer.

A design viewpoint verifying at which degrees side restraints/support is taken as well as information of the kind and also correctings of restraint A complete collection of architectural designer's computations to take the supporting reactions as well as note where they are put on the primary framework A design declaration from the project engineer mentioning they have taken account of the support responses and also included them in the layout of any kind of supporting elements The fire demands for each project (limit and height) defined by the designer/ designer to suit the needs of each job to adhere to Building Rules Spandrel Panel Building and construction Considerations In masonry dental caries wall construction situations, the list below stipulations must be applied in accordance with the structural engineer's layout: Provision for restriction of the top of the inner stonework wall where it fulfills the spandrel panel need to be provided.

Dealing with of the base of the spandrel panel to the masonry. Side restraint of the spandrel panel back to the roof covering framework (including dealing with location and kind). In both stonework and hardwood frame construction, a minimal 50mm clear tooth cavity in between the spandrel panel and also the outside stonework leaf need to be maintained.

The Buzz on Aluminum Spandrel Panel

by a tooth cavity tray. Finally, any type of tooth cavity trays must be washed by the rest membrane layer to a minimum of 100mm. The wall surface connection spacing ought to be dealt with with to the upright studs of the panel (not the sheathing panels) at centres specified in the architectural engineer's style Suitable hardwood framework wall connections should be used to link the external skin of stonework to the spandrel panel A breather membrane layer ought to constantly be incorporated on the tooth cavity side of the spandrel panel A drained as well as aerated tooth cavity requires to be maintained with a minimum 50mm clear dental caries between the spandrel panel and also the outside masonry fallen leave A condensation danger visit their website evaluation ought to be given where fire resistance requirements or inner panel lining mean that the roofing system insulation can not be proceeded right into the panel Please Note: Every treatment was required to make sure the info in this short article was proper at the time of publication.

Nonetheless, for the most as much as day LABC Service warranty technological support please refer to your Risk Management Surveyor and the newest version of the.

All About Aluminum Spandrel

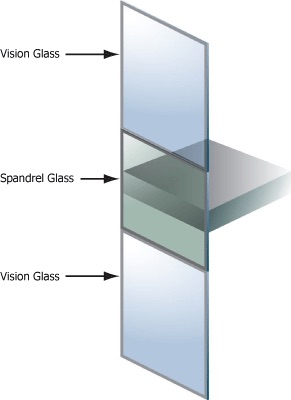

Architectural Fundamentals The word "spandrel" is a building term that refers to an archway or various other crested system of supports. Spandrel glass is one of the only sorts of glass qualified of covering this sort of structure in a manner that not just fits its curvature, however likewise creates the impression of a solitary as well as unbroken wall.

Covering these with glass can often create a more pleasing, polished appearance than would loading them in or developing a much more traditional wall surface over them. This kind of glass often tends to be opaque, and also is normally reflective. Often individuals can see from it, however in a lot of cases it really drives away light as well as frequently shows up to have a mirrored surface area.

Visual High Qualities One of the most valued aspects of this material is its capacity to create an overall consistent appearance. The glass is typically colored, and as such it can match most other sorts of glass that are made use of to create a building front. Green as well as blue tones tend to be a few of one of the most glass glazing points common, as these have the ability to show the skies with specific precision.

Numerous industrial buildings have actually been lined with spandrel glass on the within in addition to the outdoors in order to trap and also maintain solar heat, which can minimize power prices and promote "green" environmental practices. The startup prices can be high, yet the cost savings over the long term can be significant.

Our Gable Spandrel Panel Statements

The UK Structure Rules Approved Document B (fire safety), Resisting fire spread over external wall surfaces area (Quantity 1: Area 10/ Volume 2: Area 12), especially states that window spandrel panels as well as infill panels have to abide by the demands of condition 10. 5/12. 5 and also the inclusive table 10. 1/12. 1, or clause 10.

6 and Appendix B4. replacement double pane glass panels. Regulation 7( 2) puts on notifiable structures above 18m. They have to abide by the demands that assessments can not be used as a form of conformity, i. e. relocating to a screening and certification strategy that has actually been increased within the rainscreen industry over the last 3 years.

This is highly not likely with these sorts of systems when an adhesive is introduced into the panel building, as an adhesive can not be certified to EN13501 as a specific layer, and if checked as component of a system, it is unlikely to have a calofic value for the sticky layer reduced enough to attain the requirements of an A1 score.

It is worth noting that adhesive is not the only substance that can restrict a panels accreditation. Including a pay per click paint (Polyester Powder Finishing) would likewise lead to a reduction in the rating of the system, as the finish would not be able to be licensed as a solitary layer and also thus, any kind of panel with a pay per click Layer to Qualicoat 2 standards would only achieve an A2 score.

Aluminum Spandrel for Dummies

It is worth remembering it is extremely unlikely that a spandrel panel can accomplish A1 fire accreditation to EN 13501 with these sorts of systems when a glue or pay per click finish is presented right into the panel construction. That is why it is so essential to get it right when defining spandrel panels.

The only means of being particular that a spandrel panel accomplishes the called for fire ranking is to ask your supplier for proof that they have actually performed testing to the relevant standard - aluminum spandrel panel. This will certainly reassure that the spandrel panel being specified will remain in line with the needs of the amended oven infill panel 2019 Structure Rules For more information concerning our spandrel panels please call us Share this write-up:.